- HOME

- » Molding Technology

- » DIP

DIP molding is starting point of Nisseieco

DIP molding products is manufactured in 4 counties, Japan, Shanghai, Indonesia and Thailand. We are No.1 of the size of production in the industry with 35 ton production per month. Standard products is made under same management system. And also, Sol production is handled by each plant with specified in same level of compounding material. Production capacity is 100 ton per month. The biggest feature of DIP molding, is using male mold only. We can save mold cost, can reduce the initial investment load and make it possible to do low-volume production. From the characteristics of this process, it is recommended you can depend on this for the products which need accurate inside dimension, such as caps. Our group are innovating original raw material, mold and machines for our group, enabling us to serve our customer needs, suppling needed products with reliable quality in fast and cheap delivery manner.

What is DIP molding?

The biggest feature of DIP molding is use male mold only. That makes it possible to reduce mold cost significantly as compared with other molding methods. Dip mold system allow us mass production by decreasing initial investment cost, and also by increasing mold and It could not be handled by injection molding. From this characteristics, it is recommended to apply to the products which need accuracy of inside dimension.

The basic process of DIP molding

DIP molding process is, first apply release agent to male mold, immersing the preheated mold in the sol, pull up slowly and put it in a heating furnace immediately, cool down and release. Then we adjust the shape of the product by such as cutting edge as needed. Due to Its contact directly with mold, inner surface dimension has a high accuracy. Also the thickness of molding can be adjusted by preheating temperature and the viscosity of the sol. However, outside of the dimensional accuracy will be so and so. Furthermore, taking advantage of characteristics of dip molding process, we can make reverse taper, complicated shape one, forcible extraction one, etc. very difficult shaped one which other molding method could not manage. Since it use male mold only, it is possible to decrease investment cost for mold, or mass-production can be possible by increasing mold. Dip Molding is excellent production methods in a sense of cost performance. Further, due to easiness of making complicated shapes and thin product, Dip Molding is popular for surgical gloves, refueling nozzle cover of the gas station, OA equipment, cars, home appliances, etc. and also process material.

Characteristics of DIP molding of Nissei group

- Complicated shapes can be handled(You can expect to the shape that could not be molded by injection)

- Excellent product appearance

- Rich in color variations

- Easy to mass production(Depending on the conditions, especially compared to the injection molding)

- Save time from the sketch stage to mass production(Custom cap, etc.)

- Wide range of size 2φ ~ 50φ(Maximum 150φ)available

- UL-V0,ROHS compliant products also available

- Supports coating

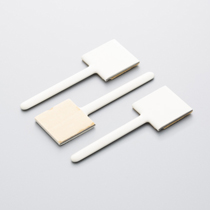

List of DIP molded product

Nisseieco “ All In One” system of ”From molding to assembling”.

Molding, R&D, mold manufacturing, assembling.

To meet various customer’s needs, providing sample is possible.