- HOME

- » Molding Technology

- » Quality Management

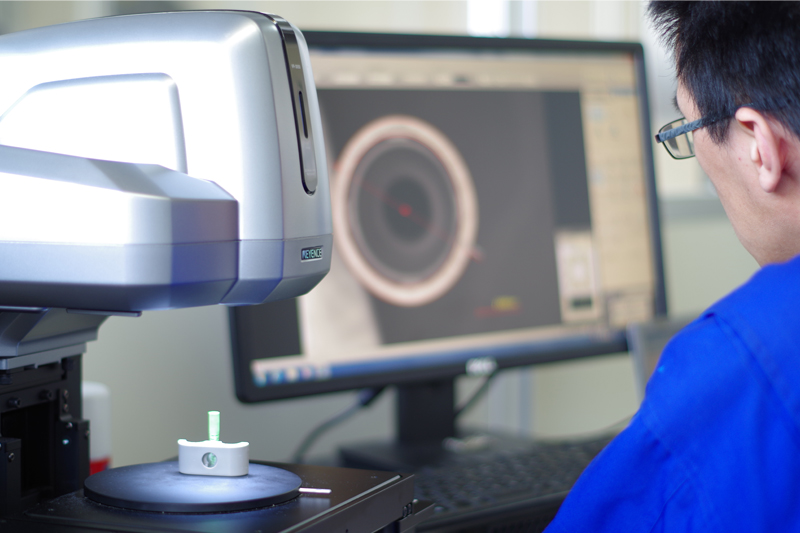

Check, collect and analyze current situation at manufacturing site

We believe that “Check, gather and analyze current situation at manufacturing Site” is the start of Quality Control. We use testing machine which is suitable to jobsite and products and assure us for checking quality of manufactured goods. Thus we received Certificate of International Quality Standards such as ISO9001, ROHS, etc. As for medical products too we make rules of check system for Safety to match for global standards as we can manage on our own. Heat resistant corrugate tube for EV, HV, PHV, etc. automotive is required strict quality control. To deliver reliable products to our customers, we are managing quality control with speed. Also, from time to time car makers and construction machinery manufacturers come to our factory to do audit of our products and instruct us for better quality products. We are leveling up quality of our products every day.

Centralized Global Quality Control

Every factory has quality control department so as to handle any problem right away. Also, every issue at oversea will be managed by headquarter to improve quality of customer service. Thus from Japan we are always ready to handle any quality matter.

Improvement of Quality Control of Our Group

We have regularly in-house global audit campaign called “Quality Cup” at our group factory. Quality Cup Campaign keep our quality level high and same of each factory. We point out factory with a problem and need to be improved and show factory with good quality control system to all other factory to improve quality. Thus competing each other keep our quality level high.

Nisseieco “ All In One” system of ”From molding to assembling”.

Molding, R&D, mold manufacturing, assembling.

To meet various customer’s needs, providing sample is possible.